6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 1. Jaw crusher. The jaw crushers are popular primary crushers for coal. They are often used in mines and quarries where large amounts of coal are mined. The working principle of the jaw crusher is to use compression force to compress coal

learn more

Coal Crusher - MoleDive Rock and Ore Crushing and

Classified as a high-efficiency fine crushing device, MoleDive’s coal crusher is specifically engineered to break down large coal chunks into smaller, more manageable fragments.

learn more

Coal Crusher China Mainland/简体中文

货号 描述 电压 / 相 / 赫兹 91-6830-01 401XL 型破碎机 230V / 3Ph / 60Hz 91-6830-02 401XL 型破碎机 230V / 1Ph / 50Hz 91-6830-05 401XL 型破碎机 230V / 1Ph / 60Hz 91-6830

learn more

煤炭破碎机_百度百科

中文名. 煤炭破碎机. 外文名. Coal crusher. 别 名. 双级破碎机. 功 能. 主要是针对高水份含量的煤炭难破碎的难题. 用 途. 一般用作粉碎煤矸石往煤里参,或者粉碎煤炭做生活之用. 目

learn more

Coal Crushers, 1.6mm / 4.75mm Final Particle Size - Gilson Co.

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke with rotary-swing hammers. The enclosed cases, covered feed hoppers, and rugged cast iron housings

learn more

coal crushing - Gaofu

Coal crushing solution. Coal has a wide range of uses, which can be summarized into three main uses according to its purpose: thermal coal, coking coal, coal chemical industry

learn more

How Do I Know Which Primary Crusher Is Best For My Coal

2019年10月17日 The primary reduction of coal from open pit or underground sources to a transportable and marketable product size, as well as further processing by cleaning

learn more

Coal crusher classification and working principle_Kefid

2024年5月21日 Coal crusher classification and working principle. Coal crusher according to the main force of its broken material can be divided into crushing coal crusher, impact

learn more

What kind of coal crusher is suitable for coal mining plants

2024年6月24日 What crusher is used for coal crushing? The roller crusher uses a pair of opposite rotating circular rollers to crush materials. It is driven by two electric motors and

learn more

coal crusher contienen

Coal Crusher - Portable Coal Crusher Latest Price, Delhi Faridabad Kolkata Hyderabad Nagpur Vadodara Chennai Amritsar Ghaziabad Ad Ecoman Steel 500 TPH Coal Crusher ₹ 23 Lakh/ Unit Get Latest Price Usage/Application: Coal Crushing Material:learn more

Coal Crusher - Portable Coal Crusher Latest Price, Delhi Faridabad Kolkata Hyderabad Nagpur Vadodara Chennai Amritsar Ghaziabad Ad Ecoman Steel 500 TPH Coal Crusher ₹ 23 Lakh/ Unit Get Latest Price Usage/Application: Coal Crushing Material:learn more

Loader Coal crushers - MB S.p.A.

Coal crusher dan screener untuk ekskavator, loader, backhoe loader dan skid loader ≥ 9 ≤ 13 Ton ≥ 8 ≤ 13 Ton ≥ 8 ≤ 13 Ton ≥ 4 10 Ton MB-HDS220 Coal crusher dan screener untuk loader, backhoe loader dan skid loader ≥ 7 ≤ 11 Ton ≥ 7 ≤ 11 Ton ≥ 4.5 ≤ 10

learn more

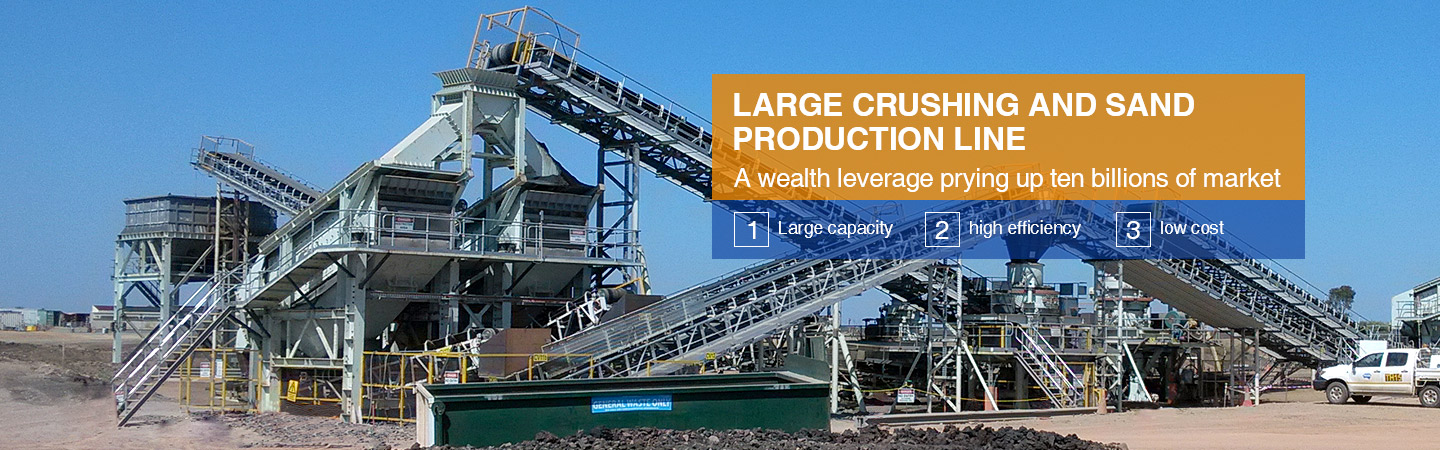

√ Apa Itu Crushing Plant? Manfaat, Jenis dan Proses Kerjanya

2024年5月3日 Pentingnya Crushing Plant terletak pada kemampuannya untuk menghasilkan material dengan ukuran yang sesuai untuk berbagai aplikasi. Material hasil dari Crushing Plant ini dapat digunakan dalam industri konstruksi untuk pembuatan beton, aspal, pasir dan kerikil, serta berbagai produk lainnya. Dengan demikian, Crushing Plant

learn more

Spring Support of Coal Crusher Foundations in Power

2024年1月11日 Spring Support of Coal Crusher Foundations in Power Plants. Such an approach usually produces a de-sign with a concrete slab on tall columns, all supported on a heavy base mat. This design attempts to resist the dynamic ef-fects and minimizes the dangers of soil settlement. Nevertheless, risks remain as this con-ventional design is

learn more

MB-HDS523, Coal crusher dan screener untuk ekskavator ...

MB-HDS523. Anda inginkan di lokasi untuk jumlah besar dan volume besar. Ini adalah yang terbesar, paling kuat dan terkuat dijajarannya. Dapatkan segala keuntungan dengan menggunakan peralatan dari MB Crusher di lokasi proyek konstruksi Anda!Untuk ...

learn more

Coal Crushers, 1.6mm / 4.75mm Final Particle Size - Gilson Co.

LC-201 model is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1,000lb (454kg) of coal material per hour. The final size is approximately 1/16in (1.6mm) and the rotor speed is 3,450rpm. Covered Feed Hopper capacity is 0.40ft³ (11.3L), and the crushing chamber is 7x6in (178x152mm).

learn more

Crushers – LT Construction Mining Machinery

LT-Kemco Jaw Crushers are used to crush virtually any mineral – hard, abrasive and of large size. It is in this demanding application that LT Jaw crushers has distinguished itself across decades – breaking the hardest of rocks of irregular shapes and sizes . LT offers a range of options in single toggle and double toggle designs.

learn more

Holmes Hammermill Coal Crusher, Feed Sizes Up To 2in

Small Holmes Hammermill Coal Crusher is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1,000lb (454kg) of coal material per hour. The final size is approximately 1/16in (1.6mm) and the rotor speed is 3,450rpm. Covered Feed Hopper capacity is 0.40ft ³ (11.3L), and the crushing chamber is 7x6in ...

learn more

How to control dust in coal crusher - LinkedIn

2024年6月17日 Here are several strategies to control dust in a coal crusher: 1. Water Sprays and Dust Suppression Systems. - Water Sprays: Applying water spray at the crushing points can help to suppress dust ...

learn more

Modeling of coal breakage in a double-roll crusher

2012年12月1日 Austin et al. [12] proposed a mathematical description of a size–mass balance model for the breakage process in a double-roll crusher. The model has been investigated in a number of studies [13], [14], [15], [16].The equation for calculating the product size distribution of the product of the roll crushing of a given feed was formulated

learn more

m/sbm coal gangue crusher is the best choice.md at main

Contribute to legaojm/m development by creating an account on GitHub.

learn more

shibang/sbm al crusher ntienen.md at master - codeberg

You've already forked shibang 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

learn more

Experimental study of coal liberation: Electrical disintegration

2009年7月1日 Ostuka Steel Company AR-85 roll crusher was used for the experiments. The roll crusher tests were carried out under various conditions and roll crusher product with a similar size distribution as the ED product was investigated further. Coal feed weight was 100 g, the same as in the ED test. 3.3. Comminution products analysis

learn more

crusher/sbm ball milling contienen.md at master

You've already forked crusher 0 Code Issues Pull requests Packages Projects Releases Wiki Activity master. crusher / sbm ball milling contienen.md. yunan88 f0aadbebe0 yes. 2022-10-27 09:53:52 +08:00. 21 KiB Raw ...

learn more

Coal Crusher Greyhound - Form, Stats News

Coal Crusher. Pindari Express x Shine Your Light. Black Dog whelped 22-04-2022 Trainer: Gary Moore (Finnie) Owner: Gary Moore. Print Current Page. Print Full Profile. Form. Stats. News.

learn more

Hammer Crusher for Coal Informasi Produk KURIMOTO, LTD. Indonesia

Demonstrates good performance in crushing coal! The Hammer Crusher is an impact crusher designed to repeatedly crush raw material between a beater head rotating at high speeds and breaker plates. Features. Excellent crushing performance. A number of hammers deliver an outstanding crushing effect.

learn more

Rub-Impact Fault Diagnosis of a Coal Crusher Machine by

2021年7月22日 The crusher was running in a coal handling plant in steel plant. A simple schematic diagram of coal crusher with sensor orientation on bearing housing, a 3D crusher model and a photograph of Crusher NDE bearing with two sensors fixed in radial and horizontal direction are shown in Figs. 4, 5 and 6 respectively. Crusher assembly was

learn more

Optimization of particle size distribution in circulating fluidized ...

2019年6月15日 The results were applied in optimizing an industrial-scale crushing system and two-toothed roll crusher of a coal gangue-fired power plant. Investigations demonstrated that the PSD can improve the combustion efficiencies of the CFB significantly by 3%, as well as a 3× extension of the original service life of the two-toothed roll crusher. ...

learn more

Analisis Efektivitas Coal Crusher Dengan Metode Overall ...

2019年10月6日 Berdasarkan hasil perhitungan nilai rata-rata OEE pada mesin coal crusher pada bulan Agustus 2018 sampai Maret 2019 sebesar 55,5% dengan nilai availability rate 78%, performance rate 77%, dan quality rate 99,9% yang dimana masih jauh dengan standar dunia yaitu Avaibility >90% performance rate >95% quality rate >99,9% .

learn more>> Next:Everest Broyeur De Pierres De Granit Ampli Kannur

Related Information:

- barmac machine concasseur

- charbon et les mines de talawi de cv

- Silicon Concasseur Spécifications

- parties de machines dans les usines

- fournisseurs de concasseurs kenyan

- l efficacité de concassage calcul broyeur

- comment fabriquer une farine de poisson maisonéquipement de Concassage

- broyage usine de balle en Chine

- petit concasseur à machines à vendre à harare

- costos de la diferentes Trituradoras Rajasthan broyeur de pierres de

- pierre prix de concasseur broyeur vertical Rockwell

- utilisé la pierre broyeuse pour les ventes de carrières de bauxite

- deferent types des ciment

- producteur pierre concasseur

- mineral concassage et de broyage circuits

- d broyeurs pour la poudre

- l'exploitation minière de dolomie à ciel ouvert

- concasseur à cone pierre marque simons

- broyage de minerais de cuivre

- sécurité dans les mines de charbon

- concasseur de pierre vente dubai utilisé

- gypse concasseur et broyeur

- schéma pour installer un concasseur

- comment utilisér un broyeur de pierres dans Minecraft sag

- utilisé concasseur a machines piste monte a vendre

- vente tom broyeur vertical principal

- sable robo rendre les taux sable robo 10513 machines faisant taux de machinerie

- la construction de routes de calcaire

- broyeur à glace électrique à vendre

- pour la vaisselle en porcelaine